Your Guide to Preventing Workplace Injuries

Discover practical strategies for preventing workplace injuries. Our guide covers safety culture, ergonomics, and risk assessment for a safer work environment.

When we talk about preventing workplace injuries, it's easy to get bogged down in rules and regulations. But the reality is much simpler and more profound: a single incident can send shockwaves through your entire organization, affecting both your people and your bottom line. Think of every safety measure you implement not as a chore, but as a direct investment in your team, your productivity, and the future of your company.

The True Cost of a Workplace Injury

When an employee gets hurt, the obvious costs—like medical bills and workers' compensation—are just the beginning. That's only the tip of the iceberg. The hidden costs are what can truly cripple a business, creating a ripple effect that touches nearly every corner of your operations.

What are these hidden costs? I’ve seen them firsthand, and they often include:

- Lost Productivity: It’s not just the injured employee who is out of commission. Someone else has to pick up the slack, often without the same level of training or efficiency. Projects get delayed, deadlines are missed, and the whole team's rhythm gets thrown off.

- Administrative Headaches: Suddenly, supervisors and HR staff are buried in paperwork. They're busy with incident reports, insurance claims, and coordinating return-to-work plans instead of focusing on their core responsibilities.

- Damaged Morale: An injury on-site can create a cloud of anxiety over the entire team. People start to worry, "Am I next?" This fear can kill motivation and create a tense atmosphere where no one feels truly safe or valued.

The Financial and Human Toll

The scale of this issue is staggering. Globally, the International Labour Organization (ILO) reports that nearly three million workers die each year from work-related accidents and illnesses.

Here in the U.S., the financial impact is enormous. The Liberty Mutual Workplace Safety Index recently revealed that the top ten most serious, non-fatal workplace injuries cost American businesses more than $58 billion every single year.

To put that into perspective, here’s a look at the most financially draining injury categories.

Top Causes of Workplace Injuries by Direct Cost

This table breaks down the top five most costly nonfatal workplace injuries in the U.S., highlighting their significant financial impact on businesses.

| Rank | Cause of Injury | Annual Direct Cost (in Billions) |

|---|---|---|

| 1 | Overexertion involving outside sources (e.g., lifting, pushing) | $12.75 |

| 2 | Falls on same level | $10.17 |

| 3 | Struck by object or equipment | $5.35 |

| 4 | Falls to lower level | $5.12 |

| 5 | Other exertions or bodily reactions (e.g., bending, reaching) | $3.71 |

Seeing these numbers makes it clear just how quickly the costs can add up. Understanding the importance of safety in the workplace is about recognizing that these aren't just abstract figures; they represent real-world consequences for your business.

A strong safety culture doesn't just prevent accidents; it builds a foundation of trust and respect. When employees see that their well-being is a genuine priority, they become more engaged, loyal, and proactive in identifying risks themselves.

At the end of the day, prioritizing injury prevention is one of the smartest business decisions you can make. It protects your most valuable asset—your people—while securing your financial stability and keeping your operations running smoothly.

Building a Culture of Proactive Safety

Preventing workplace injuries is about much more than a dusty rulebook sitting on a shelf. Real safety is woven into the daily fabric of an organization. It’s a shared mindset, not just a set of policies to follow. Creating this kind of proactive culture means shifting safety from a top-down mandate into a collective responsibility that everyone owns.

This cultural shift starts at the top. When leaders move from simply enforcing rules to actively championing safety, everything changes. Think about a manager who always wears their personal protective equipment (PPE) or kicks off a meeting with a quick safety reminder. That sends a powerful message. It shows everyone that safety is a core value, not just a compliance checkbox.

Empower Employees to Be Safety Advocates

The most successful safety programs are the ones that empower every single person on the team to be a risk spotter. This only works if you build an environment of psychological safety, where people feel comfortable pointing out potential hazards without fearing blame or getting in trouble. A "no-blame" reporting system is absolutely essential for this.

Imagine an employee sees a frayed electrical cord under a coworker's desk. In a culture of blame, they might just ignore it to avoid causing a hassle. But in a proactive culture, they report it immediately, confident that their concern will be taken seriously and handled constructively.

When you celebrate the reporting of a near-miss, you reinforce the idea that preventing a future accident is a team victory. This encourages everyone to keep their eyes open for potential issues, creating a vigilant and responsive workforce.

A strong safety culture has a direct impact on the bottom line. It leads to fewer incidents and a more resilient business. While there was an encouraging 8.4% decrease in reported nonfatal injuries in the U.S. from 2022 to 2023, there were still 2.6 million cases. Taking proactive steps doesn't just protect your people—it also boosts productivity and helps you attract top talent.

Reinforce Safety Through Open Communication

Creating this environment takes more than a suggestion box. It means actively asking for feedback and actually using it to shape your safety strategy.

Here are a few practical ways to get the conversation started:

- Regular Safety Huddles: Hold short, informal check-ins at the start of a shift or week to discuss any potential hazards or concerns.

- Anonymous Reporting Channels: Give employees a way to report issues without attaching their name, which can encourage more honest feedback.

- Integrate Safety with Wellness: Proactive safety is a crucial piece of a bigger puzzle. You can learn more about how this fits into comprehensive workplace wellness programs.

Ultimately, a robust safety culture turns your entire team into a proactive defense against accidents. It’s an ongoing conversation that makes preventing injuries a shared and genuinely achievable goal.

Mastering Ergonomics in Your Workspace

Whether you're set up in a home office or navigating a busy factory floor, getting your ergonomics right is one of the most effective ways to prevent workplace injuries. It’s all about making your environment fit you, not the other way around. When we force our bodies to adapt to a poorly designed space, we open the door to musculoskeletal disorders (MSDs), which are a huge reason people miss work.

The whole point is to maintain a natural, low-stress posture throughout your day.

If you work at a desk, the journey starts with your chair and monitor. Get this right: your feet should be flat on the floor, with your knees bent at about a 90-degree angle. Your lower back needs solid support—no slouching!

Next, look at your screen. The top of your monitor should be at or just below your eye level. This simple adjustment stops you from craning your neck forward all day. Your keyboard and mouse should be close enough that you can keep your elbows comfortably at your sides.

Fine-Tuning Your Desk Setup

Once the big pieces are in place, it’s the little tweaks that really count. I like to think of my desk as a cockpit—everything I need is within easy reach, so I'm not constantly stretching or straining in weird ways.

- Keyboard Position: Your keyboard should be placed so your wrists can stay straight. Bending them up or down is a recipe for pain. Ergonomic keyboards are great, but even a standard one can work if it's positioned correctly.

- Screen Distance: A good rule of thumb is to place your monitor about an arm's length away. This helps prevent eye strain and encourages you to sit back properly.

- Check In on Your Setup: Even the most “perfect” setup can feel off after a while. For a quick, personalized look at your current arrangement, a desk ergonomics checker can be incredibly useful for spotting problems you might have missed.

I always tell people to think of ergonomics as an ongoing process, not a "set it and forget it" task. Your work changes, so your workspace should, too. A quick five-minute review each week can save you from weeks of discomfort down the road.

Ergonomics Beyond the Office

Ergonomics is definitely not just for desk jobs. In fact, for anyone doing manual labor, these principles are even more critical. Proper lifting technique—bending at the knees instead of the waist and keeping the weight close to your body—is absolutely non-negotiable for protecting your back.

To truly get a handle on ergonomics, you have to look at all the physical stressors. This includes understanding the common manual handling hazards that can cause serious, long-term strain.

Little things can make a huge difference. For instance, providing anti-fatigue mats for people who stand all day can drastically reduce stress on their legs and back. Another game-changer is choosing tools with ergonomic grips designed to minimize vibration and prevent awkward wrist positions. These small investments in the right equipment have a massive impact on keeping your team safe and healthy.

Your Framework for Risk Assessment and Control

A truly proactive approach to preventing workplace injuries boils down to a simple idea: fix problems before they can hurt someone. Instead of just reacting after an accident happens, a structured risk assessment helps you systematically find, analyze, and neutralize potential dangers. It turns safety from a guessing game into a repeatable, reliable process.

It all starts with walking through your workspace with fresh eyes to identify hazards. You're looking for anything with the potential to cause harm. It might be something as obvious as a trailing power cord—a clear trip hazard—or a poorly lit staircase just asking for a fall. In a factory, it could be an unguarded machine or a workstation that forces people into awkward, repetitive motions that cause strain over time.

Once you’ve spotted a hazard, you need to evaluate the risk. This isn’t complicated; it just means thinking about two things: how likely is it that someone will get hurt, and how bad could that injury be? That trailing cord is highly likely to trip someone, and the result could be anything from a minor bruise to a serious fracture. This quick evaluation helps you figure out what to tackle first.

Applying the Hierarchy of Controls

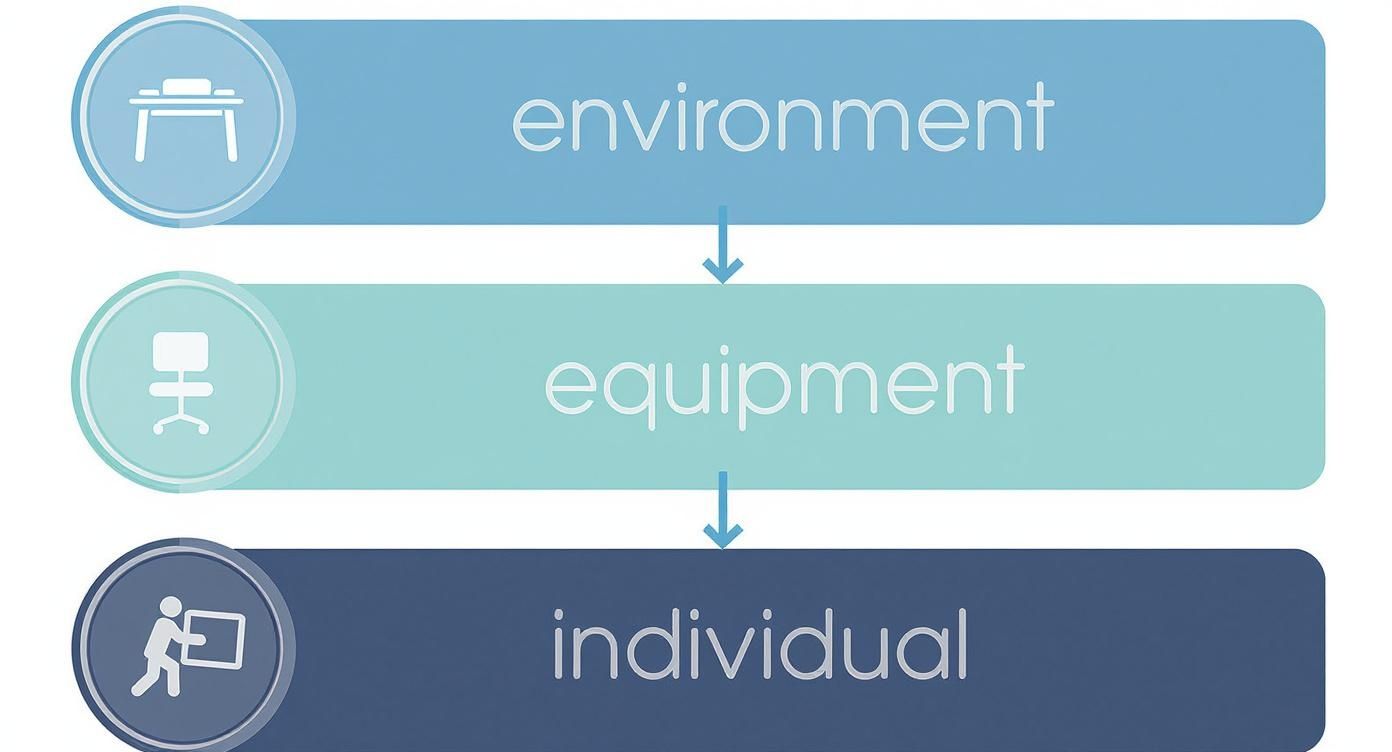

With your risks prioritized, it’s time to implement solutions using a proven model. The Hierarchy of Controls is a powerful framework that guides you toward the most effective fixes—not just the easiest or cheapest ones.

The best safety controls are always the ones that remove the hazard completely, making it impossible for an injury to occur. Relying on employee behavior alone is the weakest link in any safety plan.

Think of it as a pyramid. The most effective solutions are at the top, and the least effective are at the bottom.

As you can see, engineering a safer environment or providing better equipment offers far more reliable protection than simply telling an individual to "be more careful."

Let's walk through a common scenario: workers are repeatedly straining their backs lifting heavy boxes from the floor to a shelf. Here’s how you’d apply the hierarchy:

- Elimination (Most Effective): Could you get rid of the manual lifting entirely? Maybe the supplier could deliver items directly to the shelf, or an automated system could do the work. The hazard is gone.

- Substitution: Can you replace the heavy boxes with smaller, lighter ones? This reduces the strain, even if the task remains.

- Engineering Controls: This is about changing the environment. Could you install a conveyor belt or provide a scissor lift so no one has to physically lift the full weight?

- Administrative Controls: Here, you change the way people work. You might implement a policy for mandatory two-person lifts for anything over 25 pounds or require frequent micro-breaks to prevent fatigue.

- Personal Protective Equipment (PPE) (Least Effective): This would be something like providing back braces. It’s a last resort because it doesn't remove the hazard at all; it just tries to lessen the impact on the person.

By working your way down from the top of the hierarchy, you build a much safer and more resilient workplace.

Making Safety Training Stick

https://www.youtube.com/embed/fMpbzCv0tD0

Let's be honest, safety training often gets a bad rap. We've all been there—sitting through a dry, hour-long presentation, clicking through slides, and promptly forgetting everything by the next day. But effective training isn't about passing a quiz; it’s about building lasting muscle memory.

To really prevent workplace injuries, that knowledge needs to become second nature. This only happens when we treat safety not as a one-off event, but as an ongoing conversation reinforced through consistent, engaging practice.

Moving Beyond the Classroom

The goal is to get safety training out of the hypothetical and into the real world. When your team can immediately connect what they're learning to the tasks they perform every single day, the information actually sticks.

Here’s how to make your training more dynamic and practical:

- Toolbox Talks: Kick off a shift with a quick, five-minute chat about a specific hazard relevant to the day's work. It could be ladder safety before a big installation or proper lifting techniques before unloading a truck.

- Hands-On Drills: Don't just talk about fire safety—get people to actually practice using an extinguisher. Run through simulated emergency drills so everyone knows their role instinctively when it really counts.

- Job-Specific Scenarios: Ditch the one-size-fits-all approach. An office worker needs to understand ergonomic risks, while a warehouse employee needs hands-on coaching for operating a forklift safely.

The most impactful training always answers the question, "How does this apply to me, right now?" When a welder sees a demonstration on proper ventilation for their specific workstation, that lesson becomes far more valuable than a generic presentation on air quality.

This kind of dedicated, ongoing safety education has had a massive impact. Since the Occupational Safety and Health Act was passed back in 1971, the average number of daily worker deaths in the U.S. has dropped from around 38 to 15. This incredible progress, detailed in the AFL-CIO's latest safety report, proves that a genuine commitment to preventing workplace injuries saves lives.

For roles that involve a lot of sitting, training needs to include movement and posture. Encouraging your team to take regular micro-breaks for stretching is vital. You can even point them to a free desk exercise generator for simple, effective movements they can do at their workstations to fight off stiffness and strain.

When you make training an active, continuous process, you're not just checking a box—you're building a resilient safety culture.

Tackling Your Top Workplace Injury Questions

Putting a safety plan on paper is one thing; making it work in the real world is another. Questions always pop up. Here are some of the most common ones I hear, along with practical answers to help you navigate the challenges.

Where Should We Even Begin With Safety Improvements?

If you want to make a real impact, start at the top. The single most effective starting point is getting a genuine, visible commitment from your leadership team. Nothing changes a company's safety culture faster.

When executives and managers are out there doing safety walks, putting a real budget behind improvements, and talking about safety like it truly matters, everyone else follows suit. It signals that safety is a core value, not just another box to check. This makes every other effort, from training to risk assessments, feel urgent and important, which is how you get real buy-in from your team.

How Do We Get People to Actually Report Near Misses?

The only way to encourage near-miss reporting is to build a system with absolutely no punishment involved. You have to reframe reporting as a learning opportunity, not a chance to point fingers.

A game-changer is when leaders make a point to publicly thank employees who report potential hazards. When you can share a success story—"because of Sarah's report, we fixed this and prevented a serious fall"—you build a culture of trust. People feel safe speaking up, and you get the data you need to fix problems before an injury happens.

Are Ergonomic Chairs Really the Answer for Office Workers?

An ergonomic chair is a great tool, but it's not a magic wand. I've seen plenty of people with top-of-the-line chairs still suffering from back pain because prevention is about habits, not just hardware.

A great chair is only effective if people know how to adjust it for their specific body. Beyond that, you have to encourage movement. We weren't built to sit still for eight hours a day. Promoting short breaks to stand up and stretch every 30-60 minutes is absolutely vital. It helps combat the repetitive strain and posture problems that even the best equipment can't solve on its own.

How Often Does Safety Training Need to Happen?

Safety training can't be a one-and-done event. Think of it less like a lecture and more like an ongoing conversation.

For the big, critical topics like emergency procedures or hazard communication, you'll want formal training at least once a year and for every new hire. But that's just the foundation. You need to supplement it with more frequent, bite-sized reminders.

Here are a couple of ideas that work well:

- Weekly "Toolbox Talks": These are quick, informal huddles focused on a single, relevant risk for the week ahead.

- Monthly Safety Nudges: A short email or a poster with a simple, actionable safety tip can keep the conversation going.

The right frequency really depends on your industry's risk level, but consistency is what keeps safety at the front of everyone's mind.

Ready to transform your workday and prevent the aches and pains of prolonged sitting? DeskBreak is a simple browser extension that helps you build healthy habits with guilt-free break reminders. Take control of your well-being and stay energized, focused, and productive. Learn more and get started at https://www.deskbreak.app.